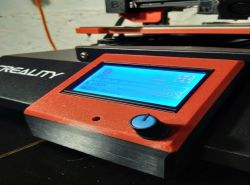

Both are double sided and really are superb, definitely the best I've ever used (and I've tried a lot!). Included in the sale are two excellent build plates from Energetic, a smooth one and a textured one. It's been working perfectly ok like this for at least the last year and a half, and through two hot summers. No fan is required in the power supply, as I removed one side of the housing and replaced it with a 3D printed mesh to allow the air to circulate around it and so cool it naturally. I have the 3D printer next to my bed and I often have it running all night with no problems - it doesn't disturb me or keep me awake at all. The part cooling fan is a 5015 blower type, and this creates the only real noise when the printer is running, and even then not much. The firmware on the printer is the superb JyersUI one, and it's awesome! There are three silent Noctua fans on the printer, one in the electronics compartment cooling the mainboard, one cooling the Raspberry Pi, and another on the Hemera which cools the hotend. I replaced the stock display housing (the display still has it's protective film!) and control knob with 3D printed alternatives, but will include the originals in case you prefer them instead. There are also heatsinks on the X and Y axis stepper motors. Since then I've added an E3D Hemera extruder/hotend (mounted to a purpose made aluminium bracket supplied by 3DFused, the same people who supplied the linear rails etc), a BL Touch clone automatic bed levelling sensor, a filament runout sensor, a filament spool holder with integrated bearings, a Raspberry Pi (in order to use OctoPrint), a Logitech C270 webcam for monitoring prints and for time lapses, silicone spacers under the bed adjusting knobs, an insulating pad for the heated bed, and a filament guide.

I bought a brand new Creality v4.2.7 silent mainboard too. I assembled the other parts as needed, added the power supply from my previous Ender 3, and wired everything together. Carbon fibre filament was also used on the four vibration dampening squash ball feet holders. It also came with twin Z axis stepper motors and lead screws, with carbon fibre filament 3D printed mounts and fittings, and anti-backlash nuts on the lead screws.

ENDER 3 V2 HEMERA UPGRADE

Attach BLTouch and fan.This is a Creality Ender 3 V2 based printer which has been fitted with almost every upgrade or add on you can think of! I bought it a couple of years ago as just the frame with the linear rails and X/Y axis brackets added (good quality 3DFused ones by the way, not cheap Chinese things from AliExpress or Banggood!), plus a few other bits and pieces from the original Ender 3 V2 kit that it started out as.Adjust the eccentric nut until the cariage does not wobble but moves freely.Hold the extruder and carriage up to the printer, and mount the 3 wheels to the carriage.Press the metal carriage into the two holes on the mount plate.Īdd two washers, a wheel and a metal spacer to each of the two bolts for the top wheels.Īdd the original washer, a wheel and the eccentric nut to the bolt for the bottom wheel.Mount the Hemera to the plate using the M3圆 bolts.

ENDER 3 V2 HEMERA UPDATE

UPDATE : Uploaded v3 based on comments from Ronny Vedå. Compact mount plate for mounting the Hemera Extruder to an Ender-3 carriage.

0 kommentar(er)

0 kommentar(er)